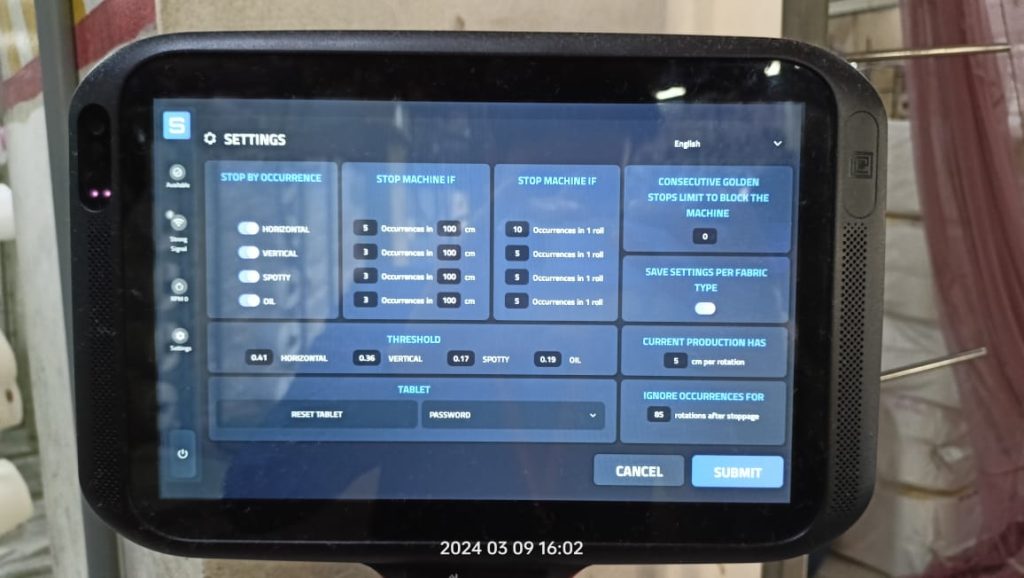

At the heart of our operations lies an AI-driven UV quality control system, which continuously monitors fabric in real-time to detect even the most minor defects. This ensures that every roll produced meets our stringent quality standards.

Key Equipment & Capabilities:

- 99 Circular Knitting Machines – Designed for speed, consistency, and versatility across various fabric types.

- 10 Flatbed Collar Cuff Machines – Delivering precision in knitting collars and cuffs.

- 6 Automated Quality Control Machines – Integrated with advanced defect detection algorithms, processing up to 700 rolls/day.

- Monthly Fleece Production Capacity: 300 Tons – Enabling bulk and custom fleece fabric solutions.

This department demonstrates how thoughtful engineering and automation can turn a moderate space into a powerhouse of textile production.

Sustainable Product Portfolio

We are committed to producing eco-friendly textiles using responsibly sourced and recycled materials. Our sustainable product range includes:

- 95% BCI Cotton / 5% Viscose Elastic Jersey – Stretchable and soft, sourced under the Better Cotton Initiative.

- 60% BCI Cotton / 40% Recycled Polyester – Promoting circular fashion through recycled fibers.

- 95% Ecovero™ / 5% Elastic – Made from renewable wood sources, providing a silky finish with a lower environmental impact.

- 35% Cotton / 65% Viscose Loop Back – Breathable and lightweight, perfect for comfortable daily wear.

Why Our 4,400 SQFT Facility Stands Out

- Efficient Production Layout with high capacity per square foot

- AI-Driven Quality Systems for real-time defect monitoring

- Balanced Output & Sustainability with both volume and eco-conscious materials

- Automated Fleece Production for consistent high-volume fulfillment

- Compact, Scalable, and Future-Ready infrastructure

Our facility proves that size isn’t everything—efficiency, intelligence, and sustainability define the future of textile manufacturing.